|

Film Bulk Acoustic-Wave Resonators |

|

Home | Contact Us | Research | Publications | People |

|

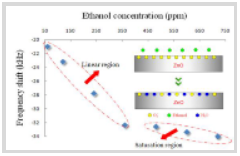

(left) Optical image for FBAR ionizing radiation sensors, (middle) SEM picture for temperature stable FBAR, (right) Calibration for FBAR Ethonol sensor.

Film Bulk Acoustic-Wave Resonators (FBAR) had remained to be of research interest or for some very niche applications since its invention in the early 1980’s. In 1993, Hewlett Packard (HP) Laboratories launched their research effort on FBAR. However, without a strong value proposition, the project was constantly in danger of being shut down. In 1998, a value proposition was proposed for applying FBAR to cell phone duplexers. It is the “killer app” for FBAR, because this technology can eliminate the large ceramic devices used in cell phones. The dramatic size reduction has clear value to the handset manufactures. In late 1998, the FBAR team (now Avago Inc.) successfully fabricated a duplexer and wired it into a working phone, which they used to make a call to their upper management. Currently, FBARs based duplexer is the dominant component for mobile devices. Besides applications in cell phones, FBAR has also drawn a lot of attention as high sensitivity mass sensors in recent years. For an acoustic mass sensor, the effect that the resonant frequency of the acoustic resonator changes in response to the mass change on the resonator surface is employed, which is called mass loading effect. Various FBAR sensors have been developed based on mass load effect. Lin and Kim investigated FBAR with antibody coating to detect TNT (Trinitrotoluene) in the environment without any pre-concentrator. The experimental results demonstrated the selectivity and long term reliability of the device. The anti-TNT antibody coated FBAR sensor was shown to produce a permanent frequency shift in response to TNT. To employing mass loading effect, generally a sensing layer is employed to attract the sensing target to improve selectivity. On the other hand, as one of the building block of the FBAR, ZnO is great material for sensing applications. Therefore, we have developed FBAR sensor platform utilizing ZnO structure layer as the sensing mechanism. This approach can eliminate the additional structures, reduce the fabrication cost and simplify the fabrication process. Various functions have been explored, including sensing Ultraviolet, Infrared, ionizing radiation, pH, humidity, Ozone and Ethanol. Due to devices’ size and they are inherently RF integratable, they are good candidates for wireless sensor network. · Z. Wang, X. Qiu, J. Shi and H. Yu, “Room Temperature Ozone Detection using ZnO based Film Bulk Acoustic Resonator (FBAR)” Journal of the Electrochemical, 2012: Volume: 159 Issue: 1 Pages: J13-J16 DOI: 10.1149/2.054201jes (pdf) · W. Pang, H. Zhao, E. S. Kim, H. Zhang, H. Yu and X. Hu, “Piezoelectric MicroelectromEchanical Resonant Sensors for Chemical and Biological Detection”, Lab on a Chip, 2012, Advance Article, DOI: 10.1039/C1LC20492K (pdf) · H. Zhang, Q. Yang, W. Pang, J. Ma, and H. Yu; “Temperature Stable Bulk Acoustic Wave Filters Enabling Integration of a Mobile Television Function in UMTS System” IEEE Microwave and Wireless Components letters, 2012: Volume: 22 Issue: 5 Pages: 239-241 DOI: 10.1109/LMWC.2012.2193123 (pdf) · X. Qiu, R. Tang, J. Zhu, J. Oiler, C. Yu, Z. Wang, and H. Yu, “The Effects of Temperature, Relative Humidity and Reducing Gases on the Ultraviolet Response of ZnO based Film Bulk Acoustic-Wave Resonator” Sensors & Actuators: B. Chemical Sensors and Actuators B, 2011: 151 360–364 (pdf) · X. Qiu, R. Tang, S.Chen, H. Zhang, W. Pang, and H. Yu, “pH Measurements with ZnO based Surface Acoustic Wave Resonator”, Electrochemistry Communications, 2011: Volume: 13 Issue: 5 Pages: 488-490 (pdf) · Z. Wang, X. Qiu, S. Chen, W. Pang, H. Zhang, J. Shi, and H. Yu, “ZnO based Film Bulk Acoustic Resonator as Infrared Sensor”, Thin Solid Films, 2011: Volume: 519 Issue: 18, Pages: 6144-6147 (pdf) · H. Zhang, W. Pang, E.S. Kim and H. Yu, “Micromachined Silicon and Polymer Probes Integrated with Film-Bulk-Acoustic-Resonator Mass Sensors”, Journal of Micromechanics and Microengineering, 2010: Volume: 20, Issue: 12, article number: 125008 (pdf) · J. Zhu, C. Lee, E.S. Kim, D. Wu, C. Hu, Q. Zhou, K.K. Shung, and H. Yu, “High-overtone Self-Focusing Acoustic Transducers for High Frequency Ultrasonic Doppler”, Ultrasonics, 2011: 50(6):544-7. (http://dx.doi.org/10.1016/j.ultras.2010.02.002) (pdf) · X. Qiu, J. Oiler, J. Zhu, Z. Wang, R. Tang, C. Yu and H. Yu, “Film Bulk Acoustic-Wave Resonator based Relative Humidity Sensor using ZnO Films”, Electrochemical and Solid-State Letters, 13, 2010, J65-J67. (pdf) · X. Qiu, R. Tang, J. Zhu, J. Oiler, C. Yu, Z. Wang, and H. Yu, “Experiment and theoretical analysis of relative humidity sensor based on film bulk acoustic-wave resonator”, Sensors and Actuators B-Chemical, 2010: v. 147, issue 2, pp: 381-384 (pdf) · W. Xu, X. Zhang, H. Yu, A. Abbaspour-Tamijani and J. Chae, “In-Liquid Quality Factor Improvement for Film Bulk Acoustic Resonators by Integration of Microfluidic Channels”, IEEE electron device letters, 2009: Volume: 30 Issue: 6 Pages: 647-652 (pdf) · X. Qiu, J. Zhu, J. Oiler, C. Yu, Z. Wang, and H. Yu, “Film Bulk Acoustic-wave Resonator Based Ultraviolet Sensor”, Applied Physics Letter, 2009: vol. 94, 16 DOI: 10.1063/1.3122342 (PDF) · H. Yu, C. Y. Lee, W. Pang, H. Zhang, A. Brannon, J. Kitching, and E. S. Kim, “HBAR-Based 3.6 GHz Oscillator with Low Power Consumption and Low Phase Noise”, IEEE Transactions on Ultrasonics Ferroelectrics and Frequency Control, 2009. 56(2): p. 400-403 (pdf) |